This week, you will receive the fifth part of our six-part series on our innovative drive system ValkScreenDrive.

In this series, we each highlight one key component of the system and explain how a recent update has made it even better prepared for today’s and tomorrow’s technological challenges.

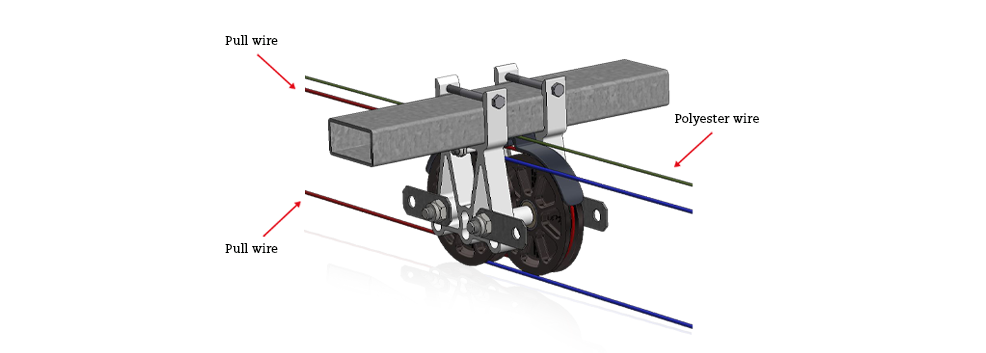

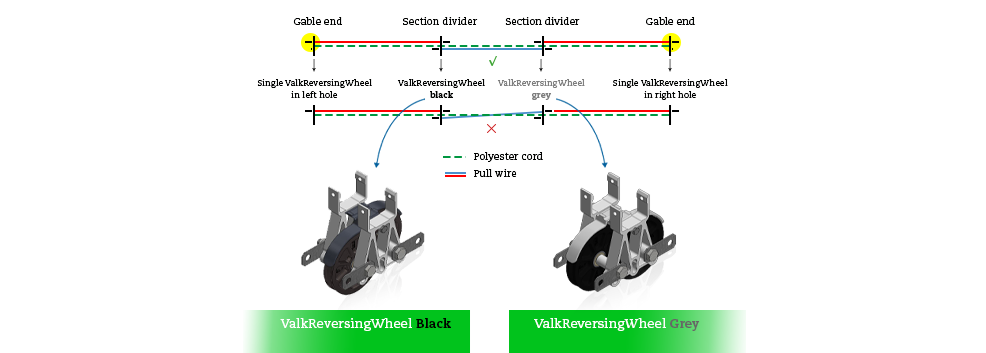

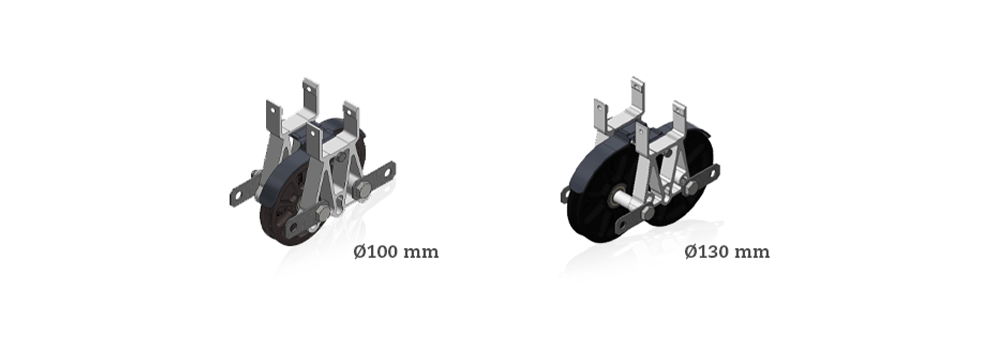

Part 1 was about the ValkDriveShaft, part 2 about the ValkBearingBracket 2.0, part 3 about the ValkWireTensioner and the ValkWireSleeve and part 4 about the ValkKliMax. Today, it's time for the next highlight: the ValkReversingWheel.