The ValkPoly+ is made up of several unique components that are perfectly aligned with each other and stand out for their functionality, quality, and ease of installation thanks to our many years of experience, in-house R&D and proprietary factory. Together, these components form an innovative and reliable screen system you can build on, now and in the future.

ValkPoly+ | The most complete screen system for poly greenhouses

Are you a screen fitter for poly greenhouses? If so, you face a challenge time and time again. How do you put together the best system from our large range of screen products? How do you make the right choice, both for yourself and for the grower?

You want to offer growers a screen system that lets them regulate the climate in their greenhouse just that little bit better. So that their crop grows just that little bit better.

And what you want for yourself is something that makes your life easier. No endless calculations with different products from different suppliers, because you generally do not have a lot of time to work out a project. And you want to stay ahead of the competition with a reliable product, quick quote, and a competitive price.

Just imagine that you could offer a complete screen system in no time, including detailed project calculation, through one single channel. Wouldn’t that be ideal?

Look no further and meet ValkPoly+: high-quality hardware at a competitive price and free, user-friendly calculation software.

✔ More complete ✔ Stronger ✔ More cost-effective ✔ Includes free software

What makes the ValkPoly+ unique?

-

The ValkScreenProfile is the basis of the system. The distinctive, unique shape makes the profile stronger than the conventional screen profile and enables perfect coupling without extra interventions or attachments. You can just slide one into the other. This means less costs for you!

Unique shape Easy to slide one into the other Perfect coupling Saves you time and money

-

The ValkWireGuide makes sure that the profile and polyester wires can move independently from each other, so that no load is placed on the structure in case of expansion and shrinkage.

Compact design. Easy to attach in the upper and lower part of the ValkScreenProfile. Prevents wear of the ValkScreenProfile. Prevents light loss thanks to black stripes on the screen cloth.

-

Free software for detailed project calculations.

Here’s how it works:- Go to www.valkhortiplanner.com, log in or create an account and start calculating.

- Use ‘Adjust floor plan’ to specify the floor plan.

- Select ‘Bill of Materials’ for a complete run-down of all the materials, including a quote

Free Easy to use Super fast

-

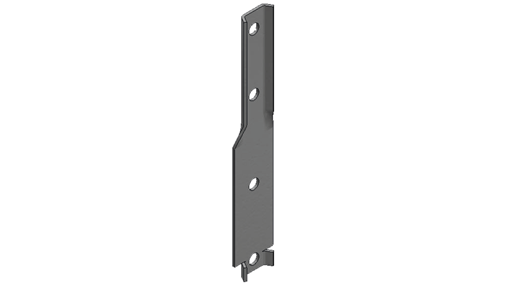

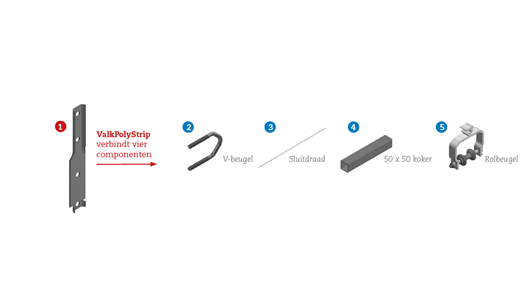

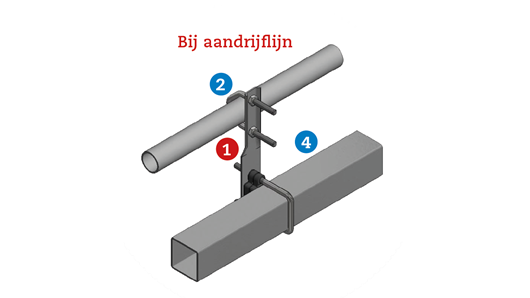

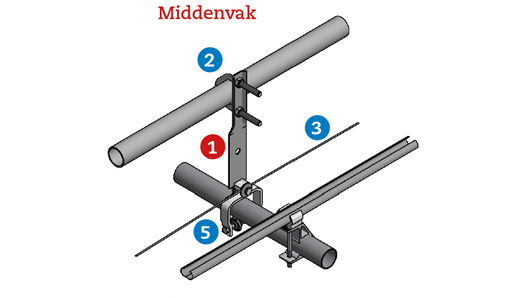

The ValkPolyStrip is the centre of the drive systems. Thanks to its smart design, it acts as a connector between as many as four components. This means you need fewer installation items, which considerably simplifies stock management needs.

Versatile Less stock

ValkScreenDrive: The right screen drive system for any poly greenhouse

With three different drive types to choose from, you will always get the right system for your greenhouse!

-

Push/pull (type 1)

-

Pull wire (type 2)

-

Semi-push/pull (type 3)

Push/pull drive system

How does it work?

Works using a push/pull tube and rack.

The push/pull tube moves to either side on a rack to open and close the screen cloth.

Unique ValkScreenDrive Type 1 components (Push/pull)

The ValkScreenDrive is made up of only a couple of multifunctional components that work in perfect harmony with each other. The ValkPolyStrip is the centre of the drive systems. Thanks to its smart design, it acts as a connector between as many as four components. This means you need fewer installation items, which considerably simplifies stock management needs.

-

The ValkDriveTube pulls and pushes the screen to open and close it.

Galvanised Contiflo tube, prevents white rust. Suitable for heavy duty (such as with darkening or shading cloth with opened ventilation windows) Available in two diameters: 27mm and 32 mm. Available in standard lengths. Easy to fix to any make rack. Reduced coupling with flange nut/flange bolt link.

-

The ValkTableClamp is the ideal connection between the ValkDriveTube and the ValkScreenProfile.

Available in versions for a 27mm and 32mm tube. Extra strong bond thanks to hollow profile. Easy and solid installation with only one bolt.

-

The ValkRollerBracket guides the ValkDriveTube.

Simple installation. Use of patented plastic rollers. Freedom of movement of the rollers effortlessly absorbs expansion differences between steel suspension tube and aluminium screen profile.

-

The ValkRollerClamp fixes the ValkDriveTube to the ValkScreenProfile in case of deviating section sizes.

The ValkRollerClamp then replaces the ValkTableClamp to guarantee a perfectly closing screen cloth in this irregular section as well.Compatible with a 27mm and a 32mm tube.

Pull wire drive system

How does it work?

Works using a steel pull wire and ValkPolyCord. This ‘cord’ can be wound around a thinner drive shaft that can be powered using a less powerful motor.

Unique ValkScreenDrive Type 2 components (Pull wire)

The ValkScreenDrive is made up of only a couple of multifunctional components that work in perfect harmony with each other.

-

The ValkPoly+ version of the ValkDriveShaft is located in the centre of the screen section. The shaft winds and unwinds the ValkPolyCord to open and close the screen.

Reduced shaft: easier to couple thanks to dual bolt/nut connection. With a 5/4” tube diameter, the system can be powered by a less powerful motor.

-

The ValkWireSleeve ensures the ValkPolyCord winds and unwinds neatly.

Suitable for installation on the 5/4” drive shaft. Grooves on the ValkWireSleeve guide the ValkPolyCord. Holes on the ValkWireSleeve indicate when the right number of windings has been reached.

-

The ValkPolyClamp makes a screen system controllable and effective, both when it comes to opening and closing the screen cloth and when it comes to regulating moisture gaps.

Delivers light gains thanks to compact structure. Unique design provides a strong bond to the ValkScreenProfile.

-

The ValkKliMax raises screen system controllability and effectiveness to the maximum level, both when it comes to opening and closing the screen cloth and when it comes to regulating moisture gaps.

The ValkKliMax ensures perfect closure in all situations, extremely uniform moisture gaps, and the smallest possible cloth package.

First aligns screen profiles for uniform moisture gaps or even heat discharge. Guarantees controlled forces on the greenhouse structure. Delivers light gains thanks to compact structure.

-

The ValkReversingWheel makes sure the stainless steel pull wire is guided along the gable and returned at a section division.

Readily available, in single or double version. Pre-installed in aluminium casing with plastic wheels. Double bearings to be able to handle greater forces. Easy to mount on standard-size profiles.

-

The ValkPulley supports the return wire of the pull wire drive (type 2), so that it cannot sag and the system will continue to run smoothly.

Multiple mounting options so it always fits. Can be opened, meaning that it can also be fixed to the return wire later. Can be opened, making it easy to remove or replace.

Semi-push/pull drive system

How does it work?

Works using the push/pull tube and ValkPolyCord.

Combines the benefits of a push/pull system with those of a pull wire system.

Unique ValkScreenDrive Type 3 components (Semi-push/pull)

The ValkScreenDrive is made up of only a couple of multifunctional components that work in perfect harmony with each other.

-

The ValkDriveTube pulls and pushes the screen to open and close it.

Galvanised Contiflo tube, prevents white rust. Suitable for heavy duty (such as with darkening or shading cloth with opened ventilation windows) Available in two diameters: 27mm and 32 mm. Available in standard lengths. Easy to fix to any make rack. Reduced coupling with flange nut/flange bolt link.

-

The ValkTableClamp is the ideal connection between the ValkDriveTube and the ValkScreenProfile.

Available in versions for a 27mm and 32mm tube. Extra strong bond thanks to hollow profile. Easy and solid installation with only one bolt.

-

The ValkRollerBracket guides the ValkDriveTube.

Simple installation. Use of patented plastic rollers. Freedom of movement of the rollers effortlessly absorbs expansion differences between steel suspension tube and aluminium screen profile.

-

The ValkPoly+ version of the ValkDriveShaft is located in the centre of the screen section. The shaft winds and unwinds the ValkPolyCord to open and close the screen.

Reduced shaft: easier to couple thanks to dual bolt/nut connection. With a 5/4” tube diameter, the system can be powered by a less powerful motor.

-

The ValkWireSleeve ensures the ValkPolyCord winds and unwinds neatly.

Suitable for installation on the 5/4” drive shaft. Grooves on the ValkWireSleeve guide the ValkPolyCord. Holes on the ValkWireSleeve indicate when the right number of windings has been reached.

-

The ValkRollerClamp fixes the ValkDriveTube to the ValkScreenProfile in case of deviating section sizes.

The ValkRollerClamp then replaces the ValkTableClamp to guarantee a perfectly closing screen cloth in this irregular section as well.Compatible with a 27mm and a 32mm tube.

Read what our partners say about their experiences with our company and our systems.

We can, of course, tell you all about how great our product is, but we prefer to leave that to our partners, who have been using our systems for years.

ValkPoly+ downloads

- Download

-

Flyer ValkPoly+Brochure ValkPoly+Brochure ValkScreenDrive

- Download

-

Promotional video | ValkPoly+ Screen System | All videos combinedPromotional video | ValkPoly+ Screen System | Part 1 - The ChallengePromotional video | ValkPoly+ Screen System | Part 2 - The basicsPromotional video | ValkPoly+ Screen System | Part 3 - The drivePromotional video | ValkPoly+ Screen System | Part 4 - The versatilityPromotional video | ValkPoly+ Screen System | Part 5 - The softwarePromotional video | ValkPoly+ Screen System | Part 6 - The conclusionValkPoly+ video | GreenTech edition 2024

- Download

-

Instruction video | ValkPoly+ Screen System| Polyester Wire KnotInstruction video | ValkPoly+ Screen System | Polyester Knot BracketInstruction video | ValkPoly+ Screen System | KnotInstruction video | ValkPoly+ Screen System | Pull WireInstruction video | ValkPoly+ Screen System | Winding ValkPolyCordInstruction video ValkPoly+ | Reversing PlateInstruction video | ValkPoly+ Screen System | Eight Knot

- Download

-

Basic Manual ValkPoly+ Pull Wire

- Download

-

Quality CertificateISO 14001 Certificate