View our unique components within the ValkScreenDrive here.

ValkScreenDrive, the versatile drive system for Venlo and Poly greenhouses

ValkScreenDrive: versatile and innovative drive system for the horticulture

The better the growing conditions, the greater the yield. The better the climate control, the greater the energy savings. A reliable screen installation is indispensable for good cultivation.

Van der Valk Horti Systems is constantly innovating to meet (future) customer needs. For example, various components of the existing drive system were recently upgraded, with which the system is fully prepared for the technological challenges of today and tomorrow. ValkScreenDrive is considered the most versatile drive system for Venlo and Poly greenhouses.

ValkScreenDrive consists of various unique components that, after the recent update, are even better matched to each other and together form one smoothly operating drive system!

ValkScreenDrive: the versatile drive system for Venlo and Poly greenhouses

With three different drive types to choose from, you will always get the right system for your greenhouse!

-

Type 1 | Push/pull

-

Type 2 | Pull wire

-

Type 3 | Semi-push/pull

Push/pull drive system

How does it work?

Works using a push/pull tube and rack.

The push/pull tube moves to either side on a rack to open and close the screen cloth.

Unique Components ValkScreenDrive Type 1 components (Push/pull)

-

The ValkDriveTube pulls and pushes the screen to open and close it.

Galvanised Contiflo tube, prevents white rust. Suitable for heavy duty (such as with darkening or shading cloth with opened ventilation windows) Available in two diameters: 27mm and 32 mm. Available in standard lengths. Easy to fix to any make rack. Reduced coupling with flange nut/flange bolt link.

-

The ValkTableClamp is the ideal connection between the ValkDriveTube and the ValkScreenProfile.

Available in versions for a 27mm and 32mm tube. Extra strong bond thanks to hollow profile. Easy and solid installation with only one bolt.

-

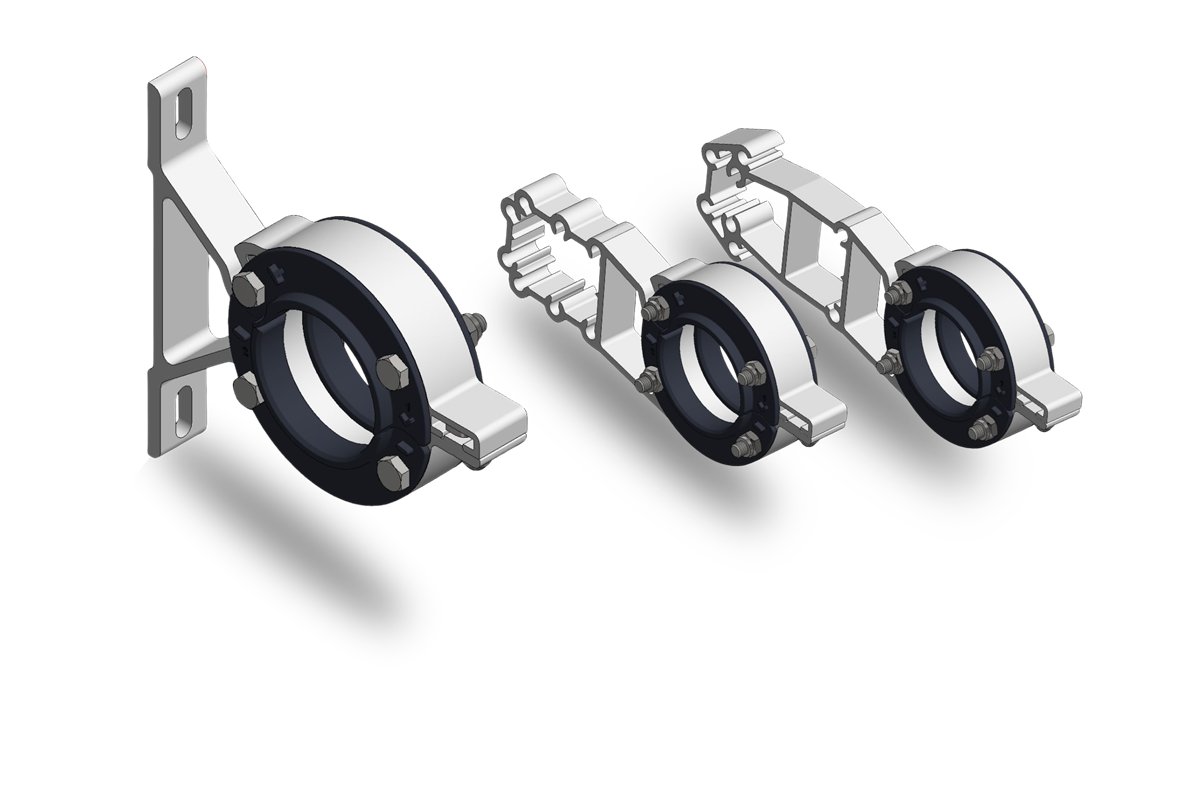

The ValkRollerBracket guides the ValkDriveTube.

Simple installation. Available both as a bolt version and as a clamp version. Use of patented plastic rollers. Freedom of movement of the rollers effortlessly absorbs expansion differences between steel truss and aluminium screen profile.

-

The ValkRollerClamp fixes the ValkDriveTube to the ValkScreenProfile in case of deviating section sizes.

The ValkRollerClamp then replaces the ValkTableClamp to guarantee a perfectly closing screen cloth in this irregular section as well.Compatible with a 27mm and a 32mm tube.

Pull wire drive system

How does it work?

Works using a stainless steel pull wire. This wire is wound around a steel drive shaft. A special tension bush ensures the wire is tensioned correctly for smooth functioning.

Unique ValkScreenDrive Type 2 components (Pull wire)

-

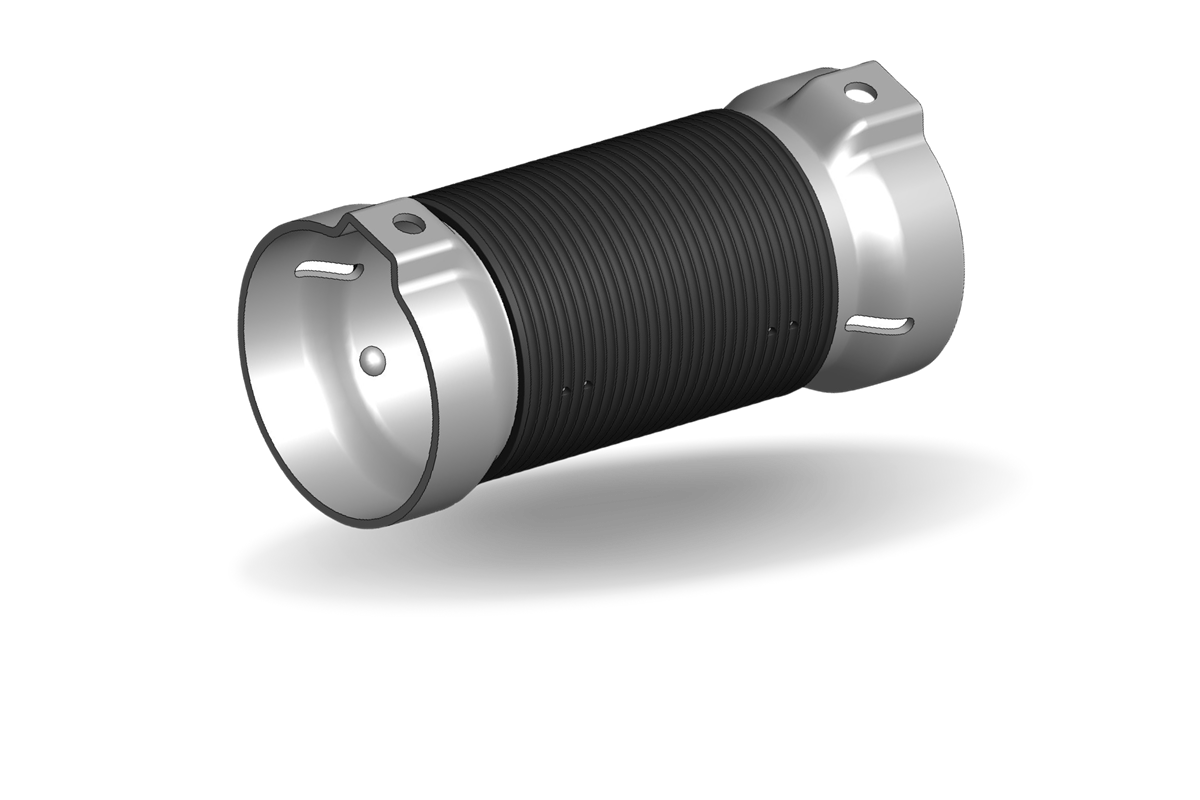

The ValkDriveShaft is located in the centre of the screen section. The shaft winds and unwinds the steel wire to open and close the screen.

The ValkDriveShaft is available in three versions:

x-reduced, o-reduced, smooth.X-reduced shaft: easy to couple with a bolt connection, with minimum play and without welding! O-reduced shaft: easier to weld together than the smooth tube. Smooth tube: can be welded together.

-

The ValkBearingBracket takes care of guiding the ValkDriveShaft and can be mounted on the greenhouse structure in various ways.

Drastically simplified installation thanks to flap functionality. No more threading through, but laying of the ValkDriveShaft. Made from one single piece of aluminium to prevent warping. Prevents notching of the drive shaft. Available with plastic sleeve bearing or with 8 ball bearings. Also available as a clamp version.

-

The ValkWireTensioner ensures that the stainless steel tensile wire is at the correct tension so that the ValkKliMax functions correctly.

The ValkWireSleeve controls the neat winding and unwinding of the pull wire.

-

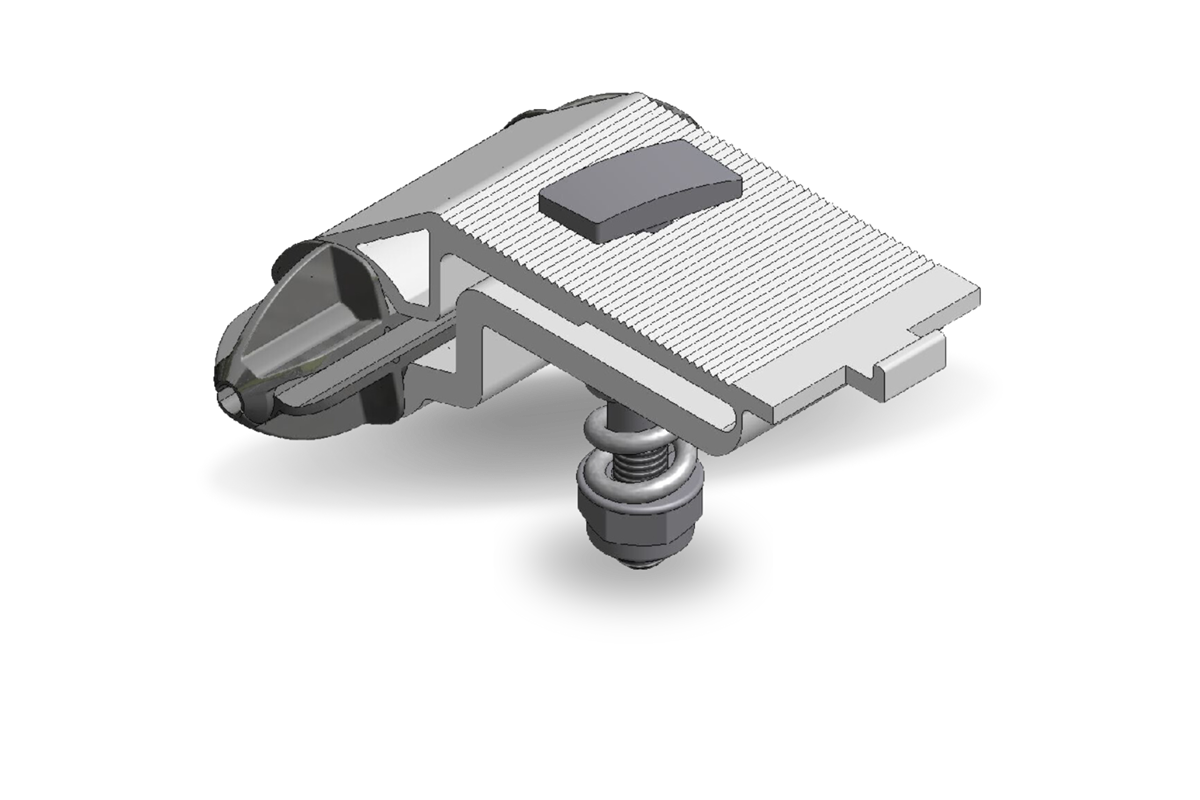

The ValkKliMax raises screen system controllability and effectiveness to the maximum level, both when it comes to opening and closing the screen cloth and when it comes to regulating moisture gaps.

The ValkKliMax ensures perfect closure in all situations, extremely uniform moisture gaps, and the smallest possible cloth package.

The most powerful of its kind with 3, 6, or 9 kilos of resistance. First aligns screen profiles for uniform moisture gaps or even heat. Guarantees controlled forces on the greenhouse structure. Delivers light gains thanks to compact structure. Various versions for maximum applicability.

-

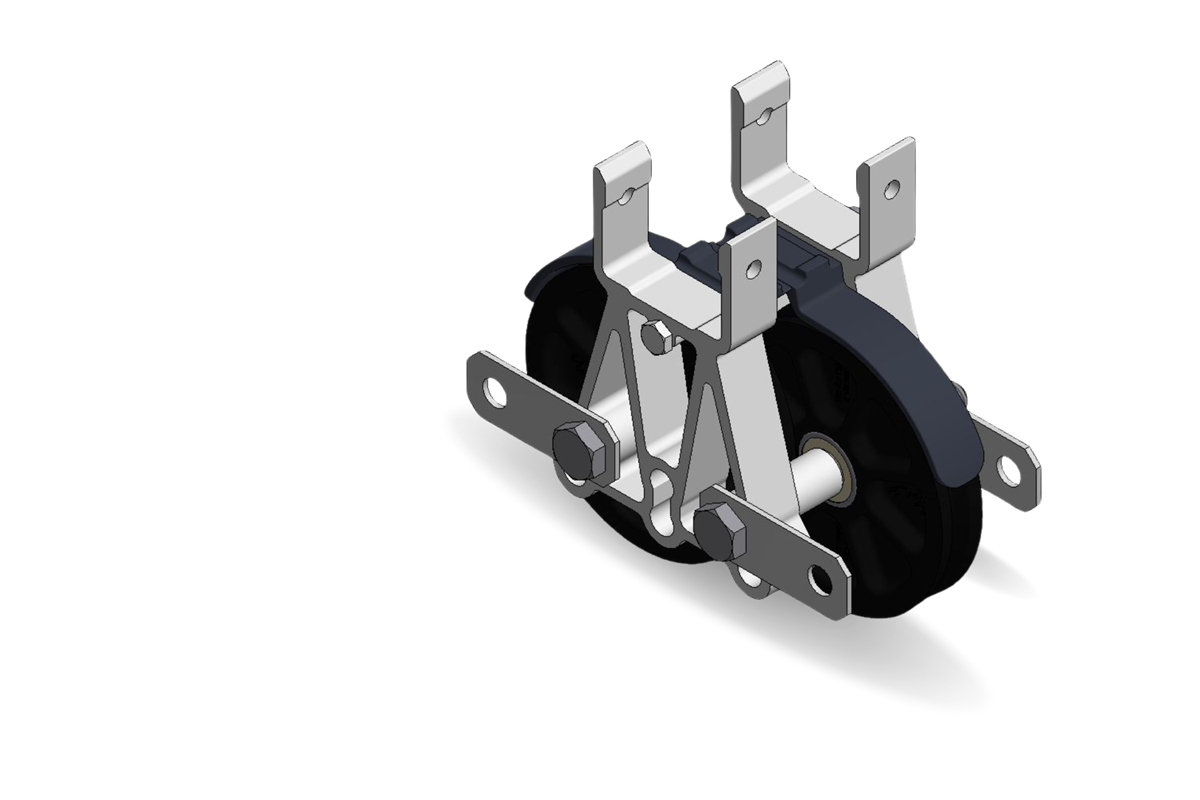

The ValkReversingWheel makes sure the stainless steel pull wire is guided along the gable and returned at a section division.

Readily available, in single or double version. Pre-installed in aluminium casing with plastic wheels. Wheels with double bearings to be able to handle greater forces. Easy to mount on standard-size profiles. Available with 100mm and 130mm wheel diameter, compatible with 3mm cable. Prevents contact with ValkKliMax with narrow profile, without needing an extension plate. Prevents screen cloth wear through the positioning of the polyester wire compared to the pull wire. Mirrored version available (double wheel) as a solution for multiple screen systems.

-

The ValkPulley supports the return wire of the pull wire drive (type 2), so that it cannot sag and the system will continue to run smoothly.

Fitted with a profile clip as standard. This clip always fits. Can be fixed to ValkScreenProfile (standard). Can be fixed to truss sleeve (optional). Can be opened, meaning that it can also be fixed to the return wire later. Can be opened, making it easy to remove or replace.

Semi-push/pull drive system

How does it work?

Works using the push/pull tube and steel pull wire.

Combines the benefits of a push/pull system with those of a pull wire system.

Unique ValkScreenDrive Type 3 components (Semi-push/pull)

-

The ValkDriveTube pulls and pushes the screen to open and close it.

Galvanised Contiflo tube, prevents white rust. Suitable for heavy duty (such as with darkening or shading cloth with opened ventilation windows) Available in two diameters: 27mm and 32 mm. Available in standard lengths. Easy to fix to any make rack. Reduced coupling with flange nut/flange bolt link.

-

The ValkTableClamp is the ideal connection between the ValkDriveTube and the ValkScreenProfile.

Available in versions for a 27mm and 32mm tube. Extra strong bond thanks to hollow profile. Easy and solid installation with only one bolt.

-

The ValkRollerBracket guides the ValkDriveTube.

Simple installation. Available both as a bolt version and as a clamp version. Use of patented plastic rollers. Freedom of movement of the rollers effortlessly absorbs expansion differences between steel truss and aluminium screen profile.

-

The ValkDriveShaft is located in the centre of the screen section. The shaft winds and unwinds the steel wire to open and close the screen.

The ValkDriveShaft is available in three versions: x-reduced, o-reduced, smooth.

X-reduced shaft: easy to couple using a bolt connection, without play and without welding! O-reduced shaft: easier to weld together than the smooth tube. Smooth tube: can be welded together.

-

The ValkWireTensioner ensures that the stainless steel tensile wire is at the correct tension so that the ValkKliMax functions correctly.

The ValkWireSleeve controls the neat winding and unwinding of the pull wire.

-

The ValkBearingBracket takes care of guiding the ValkDriveShaft and can be mounted on the greenhouse structure in various ways.

Drastically simplified installation thanks to flap functionality. No more threading through, but laying of the ValkDriveShaft. Made from one single piece of aluminium to prevent warping. Prevents notching of the drive shaft. Available with plastic sleeve bearing or with 8 ball bearings. Also available as a clamp version.

Read what our partners say about their experiences with our company and our systems.

We can, of course, tell you all about how great our product is, but we prefer to leave that to our partners, who have been using our systems for years.

ValkScreenDrive downloads

- Download

-

Brochure ValkScreenDrive

- Download

-

ISO 14001 CertificateQuality CertificateHortiQ Certificate 2023